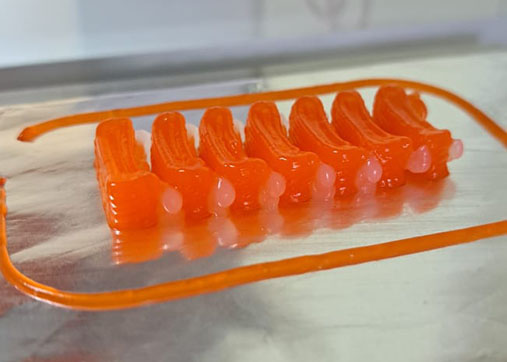

The market for so-called plant-based foods is experiencing exponential growth. To meet the demand of people with vegan, vegetarian diets or dietary restrictions, researchers from Embrapa Genetic Resources and Biotechnology produced an alternative similar to “fish fillet” using a 3D printer. The prototypes, made with ingredients based on soy flour, chickpeas and a series of fava beans, were developed at the Nanobiotechnology Laboratory (LNANO), within the scope of the 3DPulSeaFood project, co-financed by The Good Food Institute (GFI) and the Embrapa.

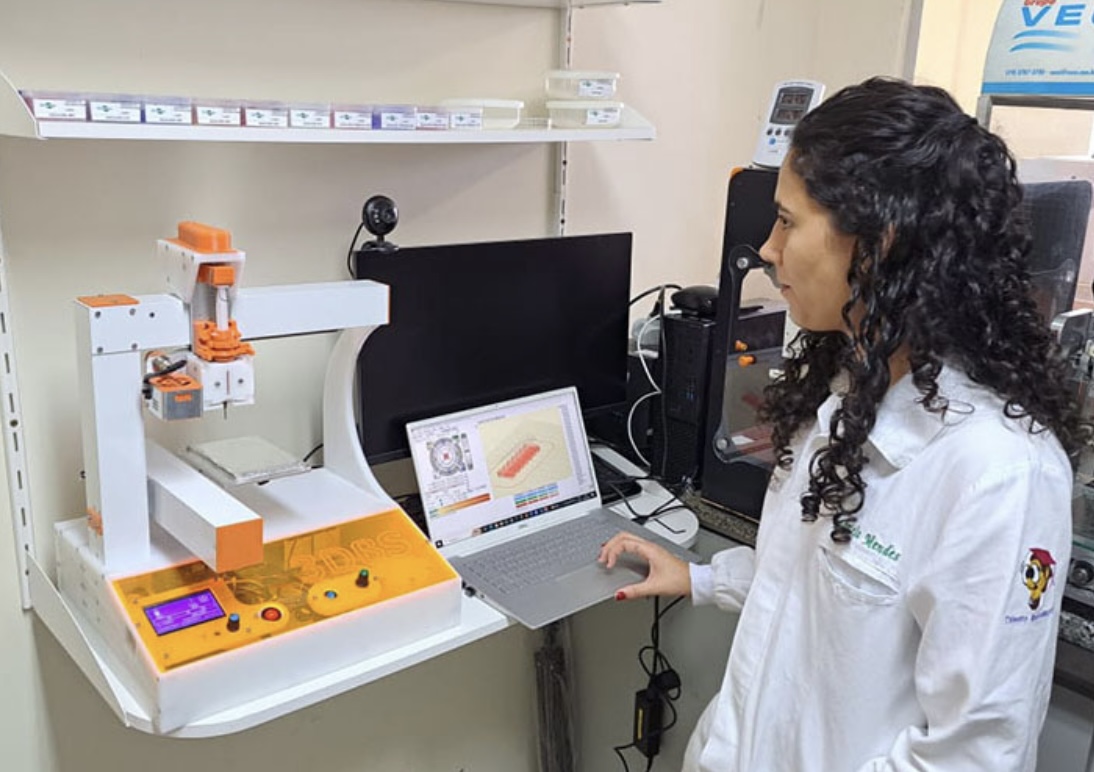

For Luciano Paulino da Silva, researcher and project leader, 3D printing is an innovative option within the plant-based food production process. “The availability of processes for the production of nuggets and hamburgers is more common, which, in general, employ other manufacturing techniques that do not make it possible to obtain the level of complexity necessary to mimic food of animal origin”, details Silva.

Now digitally manufactured prototypes are available to companies interested in taking the product to the market. According to Embrapa, the partnership with the private sector is important for carrying out the final stages of development, which includes sensory analyzes and scale tests.

Silva explains that proofs of concept and optimization in a laboratory environment have already been carried out, following computer-aided design (CAD) modeling of whole fish cuts and 3D printing of similar fish. “The images of fish of animal origin were used only as inspiration for the construction of three-dimensional models that simulate the characteristics of fish cuts”, reports the project leader.

During the development of the project there was also concern about combining high technology with sustainable development. The scientist explains that since the creation of the proposal, opportunities for transversality between the areas involved have been observed, whether in food engineering, digital manufacturing or the use of nanotechnology in the form of nanoingredients. The work used the most advanced in food engineering such as nanobiotechnology and industry 4.0.

More than just ‘hype’

Food printing should be seen as more than just hype – what’s hot. These printers, which are in the initial phase of development, according to Embrapa, allow the creation of personalized foods, with unique shapes, textures and flavors. This goes beyond a trend and can be useful for people with special dietary needs and also in hospitals.

Furthermore, this technology can also be used to create foods with high nutritional value that are also cheaper and more accessible. This can be done using low-cost ingredients, such as flour and agricultural and agro-industrial products.

(With information from Embrapa Agency)

source/credit: Katiuscia Mizokami/ Digital Agro