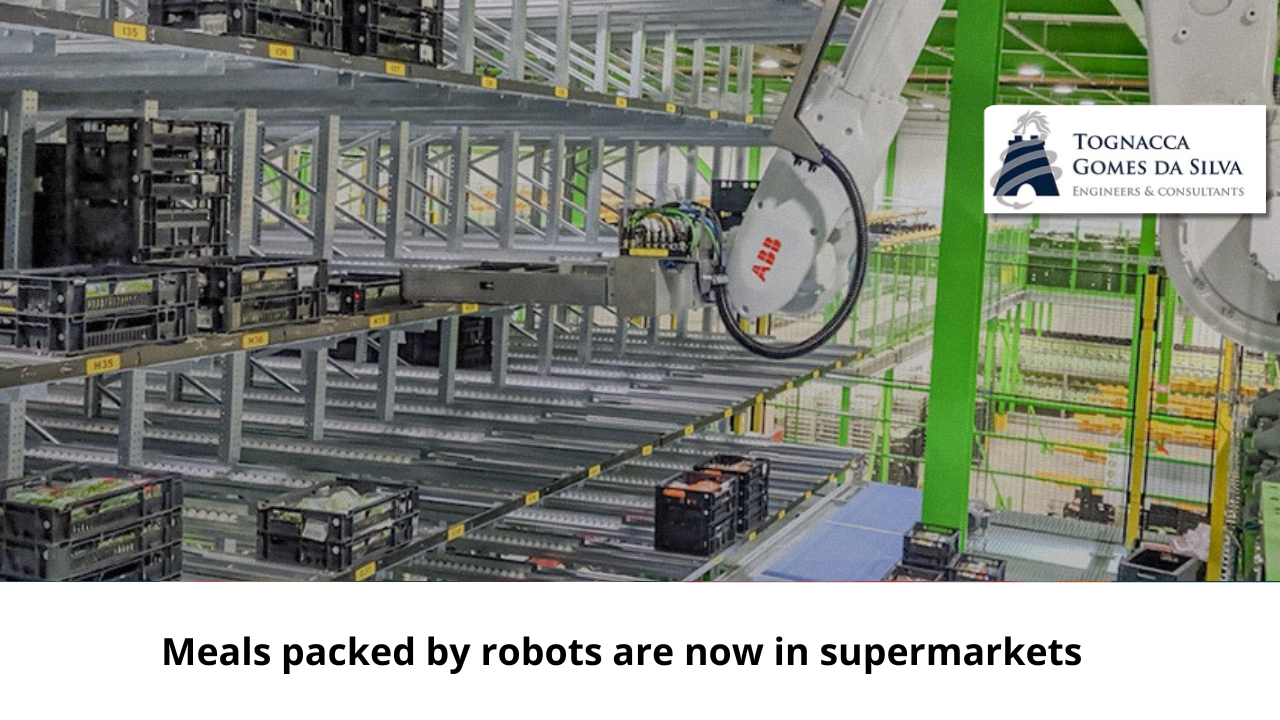

Advances in Artificial Intelligence are coming to your freezer in the form of robot-prepared meals.

Chef Robotics, a startup based in San Francisco, USA, has launched a system of AI-powered robotic arms that can be quickly programmed with a recipe to dispense precise portions of everything from chicken tikka masala (a Hindu sauce) to tortellini al pesto. (Italian pasta and sauce). After experiments with leading brands including Amy’s Kitchen, the company says its robots have proven their value and are being implemented at scale in more production facilities. They are also being offered to new customers in the US and Canada.

You might think that the meals that end up in the frozen food aisle at the supermarket, at Starbucks or on airplanes are already packed by robots, but that’s rarely the case. Workers are often much more flexible than robots and can handle production lines that rotate recipes frequently. Additionally, certain ingredients, such as rice or grated cheese, are difficult for robotic arms to portion out. This means that most brand-name meals are still packaged by hand.

However, advances in AI have changed the calculus, making robots more useful on production lines, says David Griego, senior director of Engineering at Amy’s.

“Before Silicon Valley got involved, the industry was much more like, ‘OK, we’re going to program – a robot is going to do this and that’s it,’” he recalls. For a brand with so many different meals, this wasn’t very helpful. But now the robots that Griego can add to the production line can learn that picking a batch of peas is different from picking cauliflower, and can improve their accuracy for next time: “It’s amazing how they can adapt to everyone. the different types of ingredients we use.” Meal packaging robots suddenly make a lot more financial sense.

Instead of selling machines outright, Chef uses a service model in which customers pay an annual fee, which covers maintenance and training. Currently, Amy’s uses eight systems (each with two robotic arms) spread across two of its factories. One of these systems can now do the work of two to four employees, depending on which ingredients are packaged, Griego says. Robots also reduce waste as they can pack more consistent portions than humans.

One-arm systems typically cost less than $135,000 per year, according to Chef CEO Rajat Bhageria.

With these advantages in mind, Griego envisions robots increasingly handling the meal assembly process. “I have a vision,” he says, “where the only thing people would do is operate the systems.” They would make sure ingredient hoppers and packaging materials were full, for example, and robots would do the rest.

Robot chefs have become more skilled in recent years thanks to AI, and some companies have promised that models that flip burgers and fry nuggets could provide cost savings for restaurants.

But much of this technology has been under-adopted in the restaurant industry to date, Bhageria says. This is because fast casual restaurants (a style of restaurant without table service, but unlike fast foods that offer quality food with healthy ingredients) generally only need one cook on the grill, and if a robot cannot completely replace that person because it still needs supervision, it doesn’t make much sense to use it. Packaged meal companies, however, have a bigger source of labor costs they want to reduce: plating and assembly.

“This will be the best value for money for our customers,” says Bhageria.

The notion that more flexible robots could mean wider adoption in new sectors is no surprise, says Lerrel Pinto. He leads New York University’s General Purpose Robotics and AI Laboratory and is not involved with Chef or Amy’s Kitchen.

“Many robots deployed in the real world are used in a very repetitive way, where they must perform the same action several times”, he says. Deep learning has caused a paradigm shift in recent years, sparking the idea that models with more general capabilities may not only be possible, but necessary for broader adoption.

If Chef’s robots are able to function without frequent stops for repairs or training, they could provide material savings for food companies and change the way they use human labor, Pinto calculates: “In the next few years, we will probably see a lot more companies trying to deploy these types of learning-based machines in the real world.”

A new challenge that robots have created for Amy’s, Griego notes, is maintaining the appearance of a manually packaged meal when it is assembled by one of them. One company dish, the cheese enchilada, was causing problems in particular. It’s finished with a sprinkle of cheddar by hand on top, but the Amy’s panel of examiners said the cheese in the dish, which had been packaged by a robot, seemed too spread out by the machine, causing Griego to revert to drafts.

“The first tests went very well,” he says. After a few changes, the robots are ready to take over. Amy’s plans to take them to more facilities and train them on a growing list of ingredients, indicating that it is increasingly likely that their frozen meals will, in fact, be packaged by a robot.

( fonte: MIT Technology Review )